- Potterton Ep2002 Programmer Installation Manual

- Potterton Programmer Instruction Manual Pdf

Download Installation and servicing instructions of Potterton Gold 11 kW Boiler for Free or View it Online on All-Guides.com. This version of Potterton Gold 11 kW Manual compatible with such list of devices, as: Gold 11 kW, Gold 12 kW, Gold 4 kW, Gold 6 kW, Gold 9 kW

Brand: Potterton

Potterton EP2000 and EP2002 Programmer from Pottertons. Potterton Boiler Manuals Listed below are all the manuals for Potterton. Just click on the model or the Gas council number and the manual will download at the bottom of the page. After you have downloaded the manual double click on the download for the manual to open, if. Just click on the model or the Gas council number and the manual will download at the bottom of the page. After you have downloaded the manual double click on the download for the manual to open, if you want to save the download right click. If you require the user manual click through the link above and then proceed the same. Potterton Apollo 25. Potterton EP2 Programmer Electronic 2 Channel 89418801-POTTERTON-EP2000-EP2002-EP3002-user-manual- doc.pdf - Free download as PDF File (.pdf), Text File (.txt) or read.

Category: Boiler

Type: Installation and servicing instructions

Model: Potterton Gold 11 kW , Potterton Gold 12 kW , Potterton Gold 4 kW , Potterton Gold 6 kW , Potterton Gold 9 kW

Pages: 28

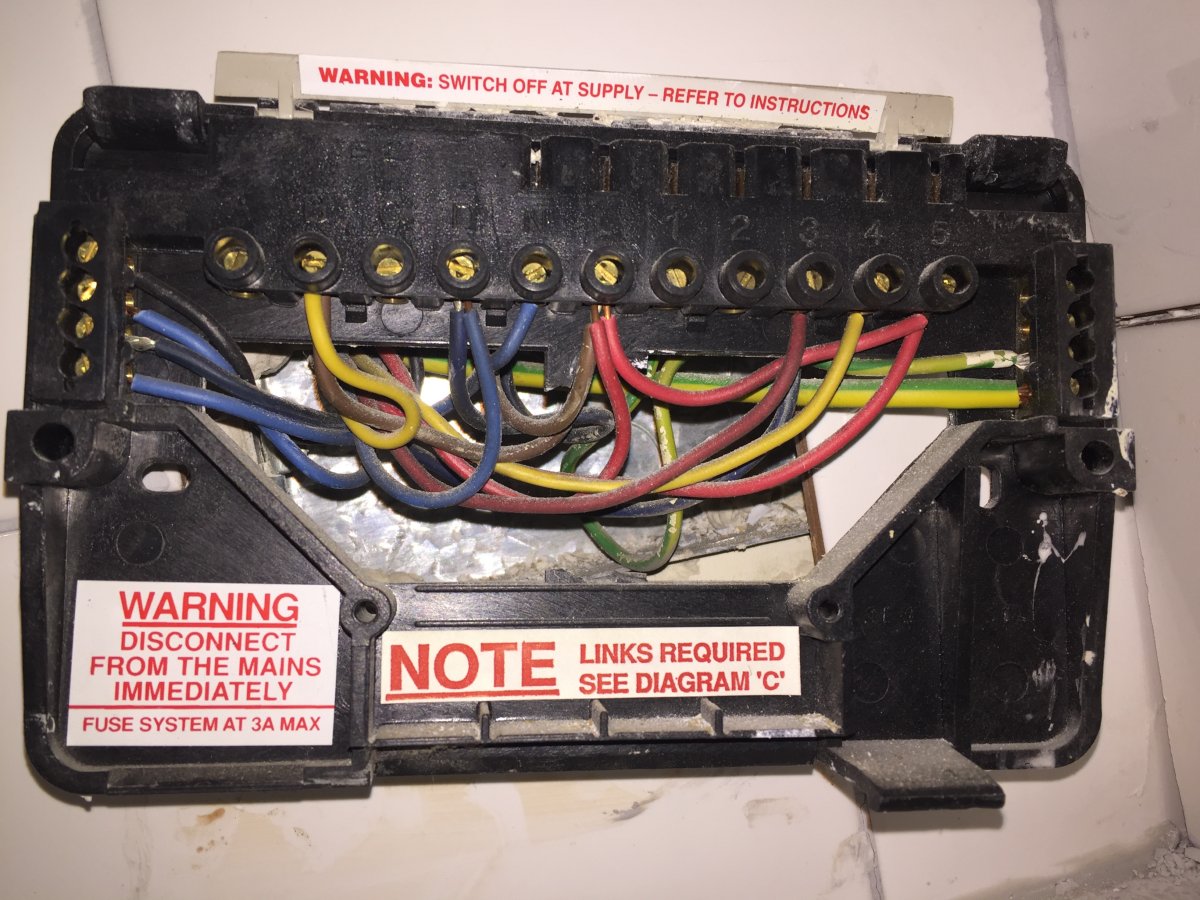

ALL WIRING MUST BE CARRIED OUT IN ACCORDANCE WITH CURRENT IEE WIRING REGULATIONS.

The POTTERTON GOLD boiler must be installed by a qualified competent tradesman in accordance

with supplied instructions and drawings to ensure correct operation.

Check the main incoming supply to the property to ensure there is sufficient current and voltage

for the size of the boiler or boilers to be installed. Remember to also take account of the supply

requirements for the rest of the property. Ensure the correct cable size is used to feed the boiler

A double pole RCD with a trip level sensitivity of 30mA and capable of breaking the full load current

In order to provide a means of isolation, the boiler must be connected to the supply through a double

pole linked switch with a minimum contact gap of 3mm in all poles. The RCD is suitable for this

requirement if it is mounted in close proximity to the boiler.

A correctly rated MCB must be used in the supply, see Technical Specifications (page 3). An additional

3A supply is required for the controls etc. NOTE, a blank must be fitted between each MCB to provide

ventilation, check with the MCB manufacturer/supplier.

NOTE: The high current mains supply MUST NOT be routed through the programmer, controls etc.

Follow the wiring diagrams. Use a standard programmer, room thermostat, etc. The high current

switching is carried out inside the boiler, only standard switched live (low current) control signals

Electrical Connections

Access can be gained to the electrical connections by removing the top front panel.

CONN 5: MAIN POWER. Main power-supply cables. Connect the power cables from the power 1.

“supply”(CONN 5) terminals onthe PCB assembly in the boiler directly to the isolation switch,live,

neutral and earth. Use the correct rated cable. Do not connect the power through the programmer,

thermostats etc. The main power PCB terminals in the boiler are suitable for cables up to 10mm

.

NOTE: THESE CONNECTIONS MUST BE TIGHT. LOOSE CONNECTIONS WILL CAUSE BURNING AT

CONN 5 CONNECTOR, THIS IS NOT COVERED BY THE WARRANTY.

CONN 1 pins 2 & 3: CONTROL SIGNAL. Connect switched live to ‘R’ and neutral to ‘N’ on the 2.

control terminal block in the boiler to the switched live and neutral from the programmer control

circuit. A neutral must be connected, as this control signal is optically isolated from the main

supply in the boiler and will not run without a neutral. Do not connect any wires to the terminal

CONN 1 pins 4, 5 & 6: PUMP CONNECTIONS. The supply to the pump must be connected to the 3.

‘PUMP’ terminal on the control terminal block in the boiler. This supply is fused in the boiler at

Cable access is made from either the right or left hand side via the x3 knockouts provided (x1 4.

25mm for power and x2 20mm for pump and thermostat cables). Having decided which side to

route the cables, remove x3 knockouts only (This can be achieved with a small tap from a ball

nose hammer, then twisting the knockout untill it is removed. Note: Take care not to damage the

casing, ensure the metal discs are retrieved and no sharp edges are present. The cables should

Potterton Ep2002 Programmer Installation Manual

be installed using a cable compression gland (not supplied).

Potterton Programmer Instruction Manual Pdf

LEFT HAND SIDE

RIGHT HAND SIDE

Related Products for Potterton Gold 4 kW

Related Manuals for Potterton Gold 4 kW

Potterton Gold 4 kW: Frequently viewed Manuals

- Products

Products

Gas boilers

Commercial solutions

Where to buy

Potterton Gold

Potterton Titanium

Discontinued boilers

Accessories and controls

- Services

Services

NewDesign

Training

Whole life costing

Potterton Hub

- Customer Support

Customer Support

Repairs

Servicing

In warranty enquiries

Genuine Parts

Maintenance plans

Technical Advice

Warranty registration

Error codes

- Advice

Advice

Winter Advice

Tenants Guide leaflets

FAQs

- Literature

- About Us

About Us

About Potterton

Mission Vision and Values

Potterton Commercial

Our History

CSR

Case Studies and News

- Legislation

Legislation

Building Regulations

ErP

EPCs

Government funding

London Boiler Cashback Scheme

Boiler Plus

- Contact us